Drive belt inspection

Inspection of the condition of the engine drive belt is performed periodically in car workshops. The correct operation of the alternator depends on the belt condition. The engine drives the alternator via a drive belt.

Inspection of the condition of the engine drive belt is performed periodically in car workshops. The correct operation of the alternator depends on the belt condition. The engine drives the alternator via a drive belt.

Alternator drive

Heat adversely affects drive belts by causing excessive hardening. Because of this, the rubber hardens and cracks. Overheating of the belt usually comes from slipping and friction. Improper belt tension or grease causes slipping. Also, the heating of the belt is transferred to the pulley bearing, which can be damaged if the slippage continues.

The V-belt fits into the groove of the pulley. The sides of the belt touch the grooves where the movement is transmitted. As the belt wears out, it begins to sink into the groove, which reduces the tension and causes slipping. Therefore, it is necessary to periodically check and adjust the tension of the belt if necessary. Tightening forces are given in the service manual for each vehicle.

If the belt is loose, it may squeal or chirp, it may squeal or chirp roll or slip off the pulley. A belt that is too tight puts pressure on the pulleys and shafts, which leads to noise, belt tearing, wear on the belt surface, and damage to the bearings and bushings on the drive components.

Check the tension of a drive belt

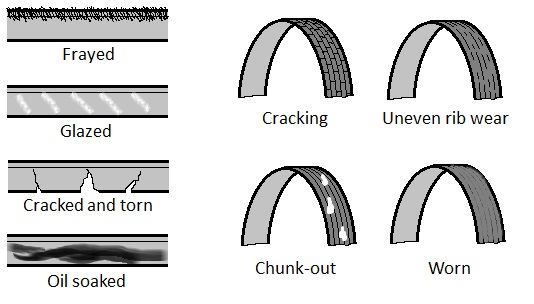

The average lifespan of a drive belt is 4 years. However, overheating, slipping, incorrect installation, over-tensioning, and other irregularities can shorten the service life. During the regular inspection of the vehicle, it is necessary to check the condition of the belts. Inspect the drive belt to see if it is worn, glazed, oil-soaked, or cracked. When the belt is damaged, it needs to be replaced. Also, check the pulleys. A damaged pulley should be replaced. The pulley should be cleaned of rust, dirt, and oil before installing the drive belt.

Drive belt condition

To perform a drive belt inspection, follow these steps:

Belt condition overview

Determine the condition of the drive belt by visual inspection. Start the engine, turn on the big consumers and watch if the belt whines. Does it have the correct position on the pulley. Is it frayed, cracked, chunk-out, glazed, oil-soaked, and other irregularities. When any irregularity is noticed, replace the belt.

Belt tension check

Check whether the belt is loose or stretched. If a change in belt tension is observed and if its condition is good, perform tensioning according to the instructions for that vehicle.

Inspection of tensioners and pulleys

Inspect the condition of the tensioner. Visually assess the condition of the pulley for damage, traces of oil, and rust. Observed irregularities should be removed.